Why circular economy in bio-economy is needed and how it can be environmentally and economically optimized at industrial plants?

Circular economy strategies are crucial to decrease the environmental impacts of human activities. Avoiding the generation of waste is a priority, followed by the reuse, repairing, reconditioning, recycling, energy recovery and, as last option, landfilling of products. Circular strategies are different for biotic and abiotic products, due to the nature of the elements in their composition. Abiotic products like metals, can be recycled an almost infinite number of times, only limited by the thermodynamic laws that lead to dissipation losses during the different separation and recovery processes of metals.

On the other hand, biotic products are those originated from living organisms like plants, for example wood. These products, in a circular economy, will follow a cascade-like life cycle, where the next application after the end-of-life of a product usually presents lower economic value. For example, the first and highest value option for a wood product is one made of solid wood. Once this product reaches its end-of-life (after being reused, repaired and refurbished) and sent to the solid waste management operator, it is impossible to treat the product in order to build a similar product made of solid wood with the same quality than the primary product. Instead, this wood needs to be fragmented into small particles to produce a new lower-value product, such as a particle board. Once this particle board reaches the end-o-life, it is really complicated to make a high value product.

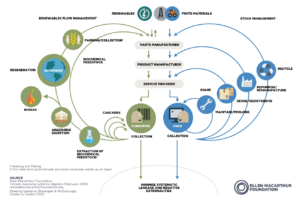

Figure 1. Butterfly diagram of a circular economy designed by Ellen MacArthur Foundation.

Instead, the next priority according to circular economy principles, is using the product as energy carrier. In this case, pellets will be manufactured and used to generate energy by combustion. After this process is carried out, most of the wood is mainly emitted to air as CO2, volatile organic compounds and particulate matter. Regarding the non-emitted fraction, only ashes will be left at the end of the process, which can have a lower value application like fillers or soil applications, although it can be also harmful for the environment and health in some cases. In order to minimize the risk and for economic reasons, ashes are usually sent to landfilling.

In this latter example, the wood-based product has been loosing value along its life cycle, from a solid wood product, to a particle board and ashes. However, in certain product systems, it is technically and economically feasible to upgrade these products and obtain a higher value product after it is used. This is the case in UP4HEALTH bio-refinery, where low value by-products (currently waste streams) from the food industry are treated to obtain high value products.

How is the sustainability assessment process in Up4Health?

ISANATUR obtains extracts and fibre rich in polyphenols and a prebiotic ingredient rich in xylo-oligosaccharides (XOS). However, the revalorization process is performed with an economic and environmental costs, linked to energy, materials and water use, which need to be assessed to evaluate the sustainability feasibility of this new value chain.

CONTACTICA is assessing the environmental, economic and social impacts using a Life Cycle Sustainability Assessment approach. Then, we are helping ISANATUR to minimize the costs and environmental and social impacts of their production process using Multi-Objective Optimization techniques to find the best operational parameters. In this way, we can ensure that the proposed biorefinery is not causing more environmental impacts than the previous scenario where most by-products are usually treated as waste. The schematical representation of the process is represented in Figure 1.

The explanation of the eco-design diagram step by step is provided below:

- XOS production process: production tests are performed in ISANATUR

- XOS Production data: data needed to build the digital simulation of the process and to perform the LCA (environmental assessment) and the economic assessment are performed.

- Environmental and Economic assessments: The data is fed into the LCA and economic assessment models to calculate the impacts results.

Figure 2. Eco-design of XOS production process scheme performed by Contactica.

- Optimisation – IA algorithm: a Multi-Objective Optimization (MOO) algorithm finds the best values for certain given parameters where ISANATUR has influence at plant. This algorithm varies these parameters, selected by ISANATUR, in the digital simulation and evaluates the influence in the LCA and economic results. This cycle is called iteration and it is performed more than 500 times. The algorithm learns in each iteration what are the main parameters for the economic and environmental optimisation of impacts.

- Results: the results provided by the MOO algorithm are communicated to ISANATUR and applied in the plant for the next real production process, and the cycle is repeated if needed.

In preliminary assessments, varying parameters that are easy to control at plant, and belong to a feasible range that do not comprise the technical feasibility of the process, a reduction of climate change and ecotoxicity impacts, as well as reduction of production costs are achieved. Currently, scaling-up strategies are being assessed and new results and eco-design strategies will be designed.

Leave A Comment